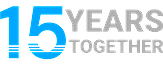

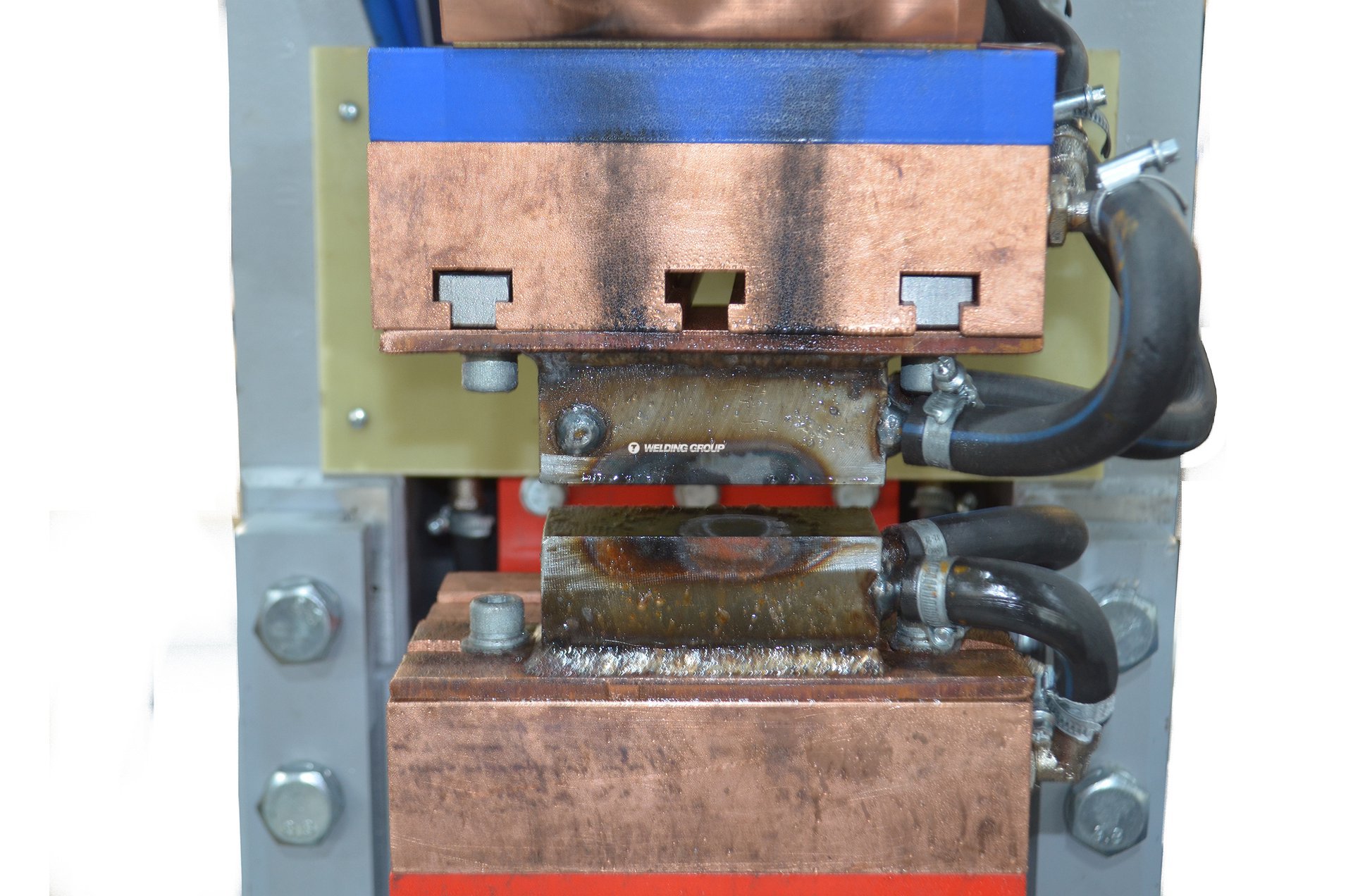

Projection resistance welding machine MR-70.07 is intended for AC welding of parts from low carbon steels, stainless steels, as well as copper busbars with welding tape thickness of 0.1; 0.2 and 0.3 mm. Maximum cross-section area of welded parts is 100x50 mm with maximum welding tape thickness of 15 mm.

Advantages of the machine MR-70.01 NF 4:

- welding current regulation when supply voltage changes;

- productivity up to 180 weld./h (several folds greater than soldering);

- no need to use copper-phosphorous and silver solders;

- reducing of labor intensity;

- stepped-phase adjustment of welding current;

- discrete adjustment of welding operation positions;

- regulator which displays the number of weldings and total operation time;

- operating in automatic and single cycle mode;

- pneumatic electrode pressure system with constant, increased and forging force;

- upper electrode travel adjustability;

- thermal protection;

- valve mufflers;

- the machine is fitted with Camozzi pneumatic equipment;

- using of an own-produced transformer TKE-140 NF4.

When welding of flexible copper busbars of large cross-section (100x100x15 mm) is considered necessary, it is required to use the MRV-70.01 NF 4 welding machine with DC supply and more powerful pneumatic cylinder.

*Please pay attention that the technical specification and the appearance of the equipment placed on this web-site are only for informational purpose and are not a public offer. The producer reserves the right to make any changes.

**Copying the data without permission of the web-site administration is prohibited.